145.A.30

145.A.30(a) Accountable manager

The organisation shall appoint an accountable manager who has corporate authority for ensuring that all maintenance required by the customer can be financed and carried out to the standard required by this Part. The accountable manager shall:

1. ensure that all necessary resources are available to accomplish maintenance in accordance with point 145.A.65(b) to support the organisation approval.

2. establish and promote the safety and quality policy specified in point 145.A.65(a).

3. demonstrate a basic understanding of this Annex (Part-145).

AMC 145.A.30(a) CEO

With regard to the accountable manager, it is normally intended to mean the chief executive officer of the approved maintenance organisation, who by virtue of position has overall (including in particular financial) responsibility for running the organisation. The accountable manager may be the accountable manager for more than one organisation and is not required to be necessarily knowledgeable on technical matters as the maintenance organisation exposition defines the maintenance standards. When the accountable manager is not the chief executive officer the competent authority will need to be assured that such an accountable manager has direct access to chief executive officer and has a sufficiency of ‘maintenance funding’ allocation.

145.A.30(b) Maintenance manager

The organisation shall nominate a person or group of persons, whose responsibilities include ensuring that the organisation complies with this Part. Such person(s) shall ultimately be responsible to the accountable manager.

1. The person or persons nominated shall represent the maintenance management structure of the organisation and be responsible for all functions specified in this Part.

2. The person or persons nominated shall be identified and their credentials submitted in a form and manner established by the competent authority.

3. The person or persons nominated shall be able to demonstrate relevant knowledge, background and satisfactory experience related to aircraft or component maintenance and demonstrate a working knowledge of this Part.

4. Procedures shall make clear who deputises for any particular person in the case of lengthy absence of the said person.

AMC 145.A.30(b) Titles of managers

1. Dependent upon the size of the organisation, the Part-145 functions may be subdivided under individual managers or combined in any number of ways.

2. The organisation should have, dependent upon the extent of approval, a base maintenance manager, a line maintenance manager, a workshop manager and a quality manager, all of whom should report to the accountable manager except in small Part-145 organisation where any one manager may also be the accountable manager, as determined by the competent authority, he/she may also be the line maintenance manager or the workshop manager.

3. The base maintenance manager is responsible for ensuring that all maintenance required to be carried out in the hangar, plus any defect rectification carried out during base maintenance, is carried out to the design and quality standards specified in 145.A.65(b). The base maintenance manager is also responsible for any corrective action resulting from the quality compliance monitoring of 145.A.65(c).

4. The line maintenance manager is responsible for ensuring that all maintenance required to be carried out on the line including line defect rectification is carried out to the standards specified in 145.A.65(b) and also responsible for any corrective action resulting from the quality compliance monitoring of 145.A.65(c).

5. The workshop manager is responsible for ensuring that all work on aircraft components is carried out to the standards specified in 145.A.65(b) and also responsible for any corrective action resulting from the quality compliance monitoring of 145.A.65(c).

6. The quality manager’s responsibility is specified in 145.A.30(c).

7. Notwithstanding the example sub-paragraphs 2 – 6 titles, the organisation may adopt any title for the foregoing managerial positions but should identify to the competent authority the titles and persons chosen to carry out these functions.

8. Where an organisation chooses to appoint managers for all or any combination of the identified Part-145 functions because of the size of the undertaking, it is necessary that these managers report ultimately through either the base maintenance manager or line maintenance manager or workshop manager or quality manager, as appropriate, to the accountable manager.

NOTE: Certifying staff may report to any of the managers specified depending upon which type of control the approved maintenance organisation uses (for example licensed engineers/independent inspection/dual function supervisors etc.) so long as the quality compliance monitoring staff specified in 145.A.65(c)(1) remain independent.

145.A.30(c) Quality manager

The accountable manager under point (a) shall appoint a person with responsibility for monitoring the quality system, including the associated feedback system as required by point 145.A.65(c). The appointed person shall have direct access to the accountable manager to ensure that the accountable manager is kept properly informed on quality and compliance matters.

AMC 145.A.30(c) Quality manager responsibilities

Monitoring the quality system includes requesting remedial action as necessary by the accountable manager and the nominated persons referred to in 145.A.30(b).

145.A.30(d) Man-hour planning

The organisation shall have a maintenance man-hour plan showing that the organisation has sufficient staff to plan, perform, supervise, inspect and quality monitor the organisation in accordance with the approval. In addition the organisation shall have a procedure to reassess work intended to be carried out when actual staff availability is less than the planned staffing level for any particular work shift or period.

AMC 145.A.30(d) Maintenance man-hour plan

1. Has sufficient staff means that the organisation employs or contracts competent staff, as detailed in the man-hour plan, of which at least half the staff that perform maintenance in each workshop, hangar or flight line on any shift should be employed to ensure organisational stability. For the purpose of meeting a specific operational necessity, a temporary increase of the proportion of contracted staff may be permitted to the organisation by the competent authority, in accordance with an approved procedure which should describe the extent, specific duties, and responsibilities for ensuring adequate organisation stability. For the purpose of this subparagraph, employed means the person is directly employed as an individual by the maintenance organisation approved under Part-145, whereas contracted means the person is employed by another organisation and contracted by that organisation to the maintenance organisation approved under Part-145.

2. The maintenance man-hour plan should take into account all maintenance activities carried out outside the scope of the Part-145 approval.

The planned absence (for training, vacations, etc.) should be considered when developing the man-hour plan.

3. The maintenance man-hour plan should relate to the anticipated maintenance work load except that when the organisation cannot predict such workload, due to the short term nature of its contracts, then such plan should be based upon the minimum maintenance workload needed for commercial viability. Maintenance work load includes all necessary work such as, but not limited to, planning, maintenance record checks, production of worksheets/cards in paper or electronic form, accomplishment of maintenance, inspection and the completion of maintenance records.

4. In the case of aircraft base maintenance, the maintenance man-hour plan should relate to the aircraft hangar visit plan as specified in AMC 145.A.25(a).

5. In the case of aircraft component maintenance, the maintenance man-hour plan should relate to the aircraft component planned maintenance as specified in 145.A.25(a)(2).

6. The quality monitoring compliance function man-hours should be sufficient to meet the requirement of 145.A.65(c) which means taking into account AMC 145.A.65(c)(1). Where quality monitoring staff perform other functions, the time allocated to such functions needs to be taken into account in determining quality monitoring staff numbers.

7. The maintenance man-hour plan should be reviewed at least every 3 months and updated when necessary.

8. Significant deviation from the maintenance man-hour plan should be reported through the departmental manager to the quality manager and the accountable manager for review. Significant deviation means more than a 25% shortfall in available man-hours during a calendar month for any one of the functions specified in 145.A.30(d).

145.A.30(e) Control of personnel competency

The organisation shall establish and control the competence of personnel involved in any maintenance, airworthiness reviews, management and/or quality audits in accordance with a procedure and to a standard agreed by the competent authority. In addition to the necessary expertise related to the job function, competence must include an understanding of the application of human factors and human performance issues appropriate to that person’s function in the organisation. ‘Human factors’ means principles which apply to aeronautical design, certification, training, operations and maintenance and which seek safe interface between the human and other system components by proper consideration of human performance. ‘Human performance’ means human capabilities and limitations which have an impact on the safety and efficiency of aeronautical operations.

AMC1 145.A.30(e) Competency assessment

Competence should be defined as a measurable skill or standard of performance, knowledge and understanding, taking into consideration attitude and behaviour.

The referenced procedure requires amongst others that planners, mechanics, specialised services staff, supervisors, certifying staff and support staff, whether employed or contracted, are assessed for competence before unsupervised work commences and competence is controlled on a continuous basis.

Competence should be assessed by evaluation of:

— on-the-job performance and/or testing of knowledge by appropriately qualified personnel, and

— records for basic, organisational, and/or product type and differences training, and

— experience records.

Validation of the above could include a confirmation check with the organisation(s) that issued such document(s). For that purpose, experience/training may be recorded in a document such as a log book or based on the suggested template in GM3 145.A.30(e).

As a result of this assessment, an individual’s qualification should determine:

— which level of ongoing supervision would be required or whether unsupervised work could be permitted.

— whether there is a need for additional training.

A record of such qualification and competence assessment should be kept.

This should include copies of all documents that attest to qualification, such as the licence and/or any authorisation held, as applicable.

For a proper competence assessment of its personnel, the organisation should consider that:

1. In accordance with the job function, adequate initial and recurrent training should be provided and recorded to ensure continued competence so that it is maintained throughout the duration of employment/contract.

2. All staff should be able to demonstrate knowledge of and compliance with the maintenance organisation procedures, as applicable to their duties.

3. All staff should be able to demonstrate an understanding of human factors and human performance issues in relation with their job function and be trained as per AMC2 145.A.30(e).

4. To assist in the assessment of competence and to establish the training needs analysis, job descriptions are recommended for each job function in the organisation. Job descriptions should contain sufficient criteria to enable the required competence assessment.

5. Criteria should allow the assessment to establish that, among others (titles might be different in each organisation):

— Managers are able to properly manage the work output, processes, resources and priorities described in their assigned duties and responsibilities in a safe compliant manner in accordance with regulations and organisation procedures.

— Planners are able to interpret maintenance requirements into maintenance tasks, and have an understanding that they have no authority to deviate from the maintenance data.

— Supervisors are able to ensure that all required maintenance tasks are carried out and, where not completed or where it is evident that a particular maintenance task cannot be carried out to the maintenance data, then such problems will be reported to the 145.A.30(c) person for appropriate action. In addition, for those supervisors, who also carry out maintenance tasks, that they understand such tasks should not be undertaken when incompatible with their management responsibilities.

— Mechanics are able to carry out maintenance tasks to any standard specified in the maintenance data and will notify supervisors of defects or mistakes requiring rectification to re-establish required maintenance standards.

— Specialised services staff are able to carry out specialised maintenance tasks to the standard specified in the maintenance data. They should be able to communicate with supervisors and report accurately when necessary.

— Support staff are able to determine that relevant tasks or inspections have been carried out to the required standard.

— Certifying staff are able to determine when the aircraft or aircraft component is ready to release to service and when it should not be released to service.

— Quality audit staff are able to monitor compliance with Part-145 identifying noncompliance in an effective and timely manner so that the organisation may remain in compliance with Part-145.

Competence assessment should be based upon the procedure specified in GM2 145.A.30(e).

GM2 145.A.30(e) Competency assessment procedure

The organisation should develop a procedure describing the process of competence assessment of personnel. The procedure should specify:

— persons responsible for this process,

— when the assessment should take place,

— credits from previous assessments,

— validation of qualification records,

— means and methods for the initial assessment,

— means and methods for the continuous control of competence including feedback on personnel performance,

— competences to be observed during the assessment in relation with each job function,

— actions to be taken when assessment is not satisfactory,

— recording of assessment results.

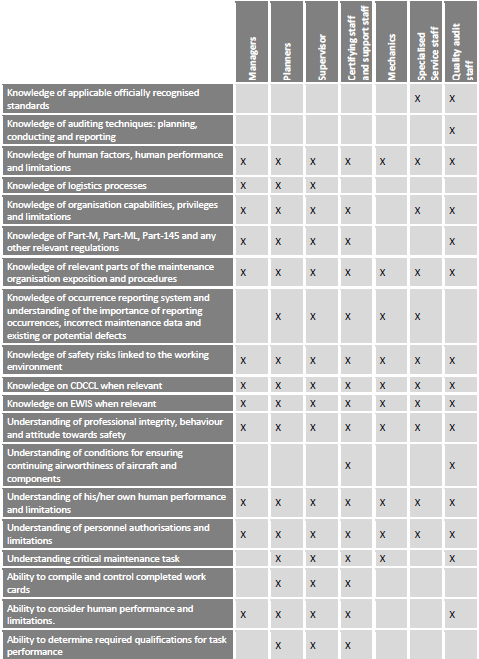

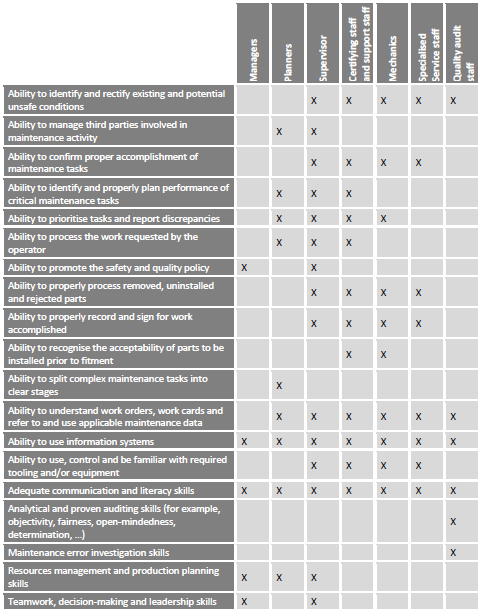

For example, according to the job functions and the scope, size and complexity of the organisation, the assessment may consider the following (the table is not exhaustive):

AMC2 145.A.30(e) Human factors training

In respect to the understanding of the application of human factors and human performance issues, all maintenance organisation personnel should have received an initial and continuation human factors training. This should concern to a minimum:

— Post-holders, managers, supervisors;

— Certifying staff, support staff and mechanics;

— Technical support personnel such as planners, engineers, technical record staff;

— Quality control/assurance staff;

— Specialised services staff;

— Human factors staff/human factors trainers;

— Store department staff, purchasing department staff;

— Ground equipment operators.

1. Initial human factors training should cover all the topics of the training syllabus specified in GM1 145.A.30(e) either as a dedicated course or else integrated within other training. The syllabus may be adjusted to reflect the particular nature of the organisation. The syllabus may also be adjusted to meet the particular nature of work for each function within the organisation. For example:

— small organisations not working in shifts may cover in less depth subjects related to teamwork and communication;

— planners may cover in more depth the scheduling and planning objective of the syllabus and in less depth the objective of developing skills for shift working.

All personnel, including personnel being recruited from any other organisation should receive initial human factors training compliant with the organisation’s training standards prior to commencing actual job function, unless their competence assessment justifies that there is no need for such training. Newly directly employed personnel working under direct supervision may receive training within 6 months after joining the maintenance organisation.

2. The purpose of human factors continuation training is primarily to ensure that staff remain current in terms of human factors and also to collect feedback on human factors issues. Consideration should be given to the possibility that such training has the involvement of the quality department. There should be a procedure to ensure that feedback is formally passed from the trainers to the quality department to initiate action where necessary.

Human factors continuation training should be of an appropriate duration in each two year period in relation to relevant quality audit findings and other internal/external sources of information on human errors in maintenance available to the organisation.

3. Human factors training may be conducted by the maintenance organisation itself, or independent trainers, or any training organisations acceptable to the competent authority.

4. The human factors training procedures should be specified in the maintenance organisation exposition.

GM1 145.A.30(e) Training syllabus for initial human factors training

The training syllabus below identifies the topics and subtopics to be addressed during the human factors training.

The maintenance organisation may combine, divide, change the order of any subject of the syllabus to suit its own needs, as long as all subjects are covered to a level of detail appropriate to the organisation and its personnel.

Some of the topics may be covered in separate training (health and safety, management, supervisory skills, etc.) in which case duplication of training is not necessary.

Where possible, practical illustrations and examples should be used, especially accident and incident reports.

Topics should be related to existing legislation, where relevant. Topics should be related to existing guidance/advisory material, where relevant (e.g. ICAO HF Digests and Training Manual).

Topics should be related to maintenance engineering where possible; too much unrelated theory should be avoided.

1. General/Introduction to human factors

1.1. Need to address human factors

1.2. Statistics

1.3. Incidents

2. Safety Culture/Organisational factors

3. Human Error

3.1. Error models and theories

3.2. Types of errors in maintenance tasks

3.3. Violations

3.4. Implications of errors

3.5. Avoiding and managing errors

3.6. Human reliability

4. Human performance & limitations

4.1. Vision

4.2. Hearing

4.3. Information-processing

4.4. Attention and perception

4.5. Situational awareness

4.6. Memory

4.7. Claustrophobia and physical access

4.8. Motivation

4.9. Fitness/Health

4.10. Stress

4.11. Workload management

4.12. Fatigue

4.13. Alcohol, medication, drugs

4.14. Physical work

4.15. Repetitive tasks/complacency

5. Environment

5.1. Peer pressure

5.2. Stressors

5.3. Time pressure and deadlines

5.4. Workload

5.5. Shift Work

5.6. Noise and fumes

5.7. Illumination

5.8. Climate and temperature

5.9. Motion and vibration

5.10. Complex systems

5.11. Hazards in the workplace

5.12. Lack of manpower

5.13. Distractions and interruptions

6. Procedures, information, tools and practices

6.1. Visual Inspection

6.2. Work logging and recording

6.3. Procedure – practice/mismatch/norms

6.4. Technical documentation – access and quality

6.5. Critical maintenance tasks and error-capturing methods (independent inspection, reinspection, etc.)

7. Communication

7.1. Shift/Task handover

7.2. Dissemination of information

7.3. Cultural differences

8. Teamwork

8.1. Responsibility

8.2. Management, supervision and leadership

8.3. Decision making

9. Professionalism and integrity

9.1. Keeping up to date; currency

9.2. Error provoking behaviour

9.3. Assertiveness

10. Organisation’s HF program

10.1. Reporting errors

10.2. Disciplinary policy

10.3. Error investigation

10.4. Action to address problems

10.5. Feedback

AMC3 145.A.30(e) Additional training requirements

Additional training in fuel tank safety as well as associated inspection standards and maintenance procedures should be required for maintenance organisations’ technical personnel, especially technical personnel involved in the compliance of CDCCL tasks.

EASA guidance is provided for training to maintenance organisation personnel in Appendix IV to AMC 145.A.30(e) and 145.B.10(3).

AMC4 145.A.30(e) EWIS training

Competence assessment should include the verification for the need of additional EWIS training when relevant.

EASA guidance is provided for EWIS training programme to maintenance organisation personnel in AMC 20-22.

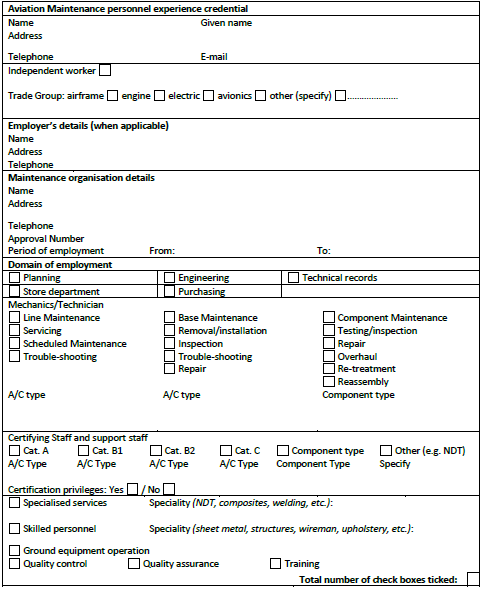

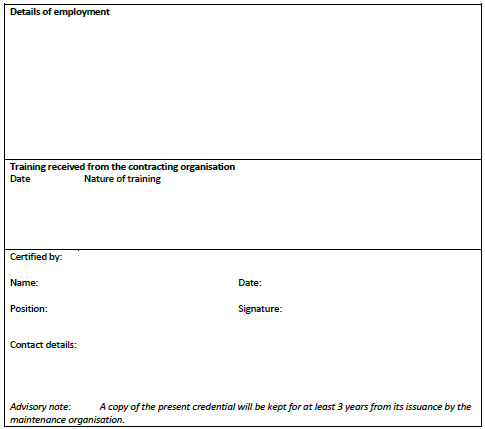

GM3 145.A.30(e) Competence assessment form

The following template may be used to record the professional experience gained in an organisation and the training received and be considered during the competence assessment of the individual in another organisation.

EASA policy on Certificates of Release to Service for aircraft maintenance and associated responsibilities of maintenance organisations and CAMO

What is the function of personnel authorised to “sign-off”? AMC 145.A.65 states that, in order to prevent omissions, every task or group of tasks should be signed-off by formally authorised personnel after its completion. It also states that a “sign-off” is different from a “release to service”. Furthermore, this AMC states that work by “unauthorised personnel” (temporary staff, trainee..) should be checked by “authorised personnel” before they sign-off. “They” means “authorised personnel” (formally authorised to sign-off). This concept of personnel authorised to sign-off is in line with the provisions related to the assessment of mechanics contained in AMC 145.A.30(e)(3). This assessment should guarantee that “mechanics shall be able to carry out tasks to any standard specified in the maintenance data, and will notify supervisors of mistakes requiring rectification to re-establish required maintenance standards”. Nevertheless, holding a “sign off” authorisation doesn’t mean that the authorised person can sign-off all tasks. It means that he/she can sign-off tasks up to the authorised level, depending on the training and experience held, and in accordance with a procedure described in the MOE. Furthermore, even if this person is qualified and able to carry out the task to the required standard, this does not mean that certifying staff and support staff are not needed. The presence of certifying staff and support staff is an additional safety barrier and, as explained in Sections 6 and 7 above, has the function of coordinating the different tasks, supporting those mechanics in case of any mistakes or unexpected difficulties and verifying that the job has been completed and signed-off properly.

145.A.30(f) NDT personnel qualifications

The organisation shall ensure that personnel who carry out or control a continued-airworthiness non-destructive test of aircraft structures or components, or both, are appropriately qualified for the particular non- destructive test in accordance with the European or equivalent standard recognised by the Agency. Personnel who carry out any other specialised task shall be appropriately qualified in accordance with officially recognised standards. By derogation from this point, personnel referred to in point (g), points (h)(1) and (h)(2), qualified in category B1, B3 or L in accordance with Annex III (Part-66), may carry out and/or control colour contrast dye penetrant tests.

AMC 145.A.30(f) Non-destructive testing

1. Continued airworthiness non-destructive testing means such testing specified by the type certificate holder /aircraft or engine or propeller manufacturer in accordance with the maintenance data as specified in 145.A.45 for in service aircraft/aircraft components for the purpose of determining the continued fitness of the product to operate safely.

2. Appropriately qualified means to Level 1, 2 or 3 as defined by the European Standard EN 4179 dependent upon the non-destructive testing function to be carried out.

3. Notwithstanding the fact that Level 3 personnel may be qualified via EN 4179 to establish and authorise methods, techniques, etc., this does not permit such personnel to deviate from methods and techniques published in the maintenance data, unless the maintenance data the expressly permits such deviation.

4. Notwithstanding the general references in EN 4179 to a national aerospace non-destructive testing (NDT) board, all examinations should be conducted by personnel or organisations under the general control of such a board. In the absence of a national aerospace NDT board, the aerospace NDT board of another Member State should be used, as defined by the competent authority.

5. Particular non-destructive test means any one or more of the following; Dye penetrant, magnetic particle, eddy current, ultrasonic and radiographic methods including X ray and gamma ray.

6. It should be noted that new methods are and will be developed, such as, but not limited to thermography and shearography, which are not specifically addressed by EN 4179. Until the time this agreed standard is established, such methods should be carried out in accordance with the particular equipment manufacturer’s recommendations including any training and examination process to ensure competence of the personnel in the process.

7. Any maintenance organisation approved under Part-145 that carries out NDT should establish NDT specialist qualification procedures detailed in the exposition and accepted by the competent authority.

8. Boroscoping and other techniques such as delamination coin tapping are non-destructive inspections rather than non-destructive testing. Notwithstanding such differentiation, the maintenance organisation should establish an exposition procedure accepted by the competent authority to ensure that personnel who carry out and interpret such inspections are properly trained and assessed for their competence in the process. Non-destructive inspections, not being considered as NDT by Part-145 are not listed in Appendix II under class rating D1.

9. The referenced standards, methods, training and procedures should be specified in the maintenance organisation exposition.

10. Any such personnel who intend to carry out and/or control a non-destructive test for which they were not qualified prior to the effective date of Part-145 should qualify for such non-destructive test in accordance with EN 4179.

11. In this context officially recognised standard means those standards established or published by an official body whether having legal personality or not, which are widely recognised by the air transport sector as constituting good practice.

145.A.30(g) Certifying staff (CRS staff)

Any organisation maintaining aircraft, except where stated otherwise in point (j), shall in the case of aircraft line maintenance, have appropriate aircraft-rated certifying staff qualified as category B1, B2, B2L, B3 and L, as appropriate, in accordance with Annex III (Part-66) and point 145.A.35.

In addition such organisations may also use appropriately task-trained certifying staff holding the privileges set out in points 66.A.20(a)(1) and 66.A.20(a)(3)(ii) and qualified in accordance with Annex III (Part-66) and point 145.A.35 to carry out minor scheduled line maintenance and simple defect rectification. The availability of such certifying staff shall not replace the need for category B1, B2, B2L, B3 and L certifying staff, as appropriate.

AMC 145.A.30(g) Certifying staff requirements

1. For the purposes of 66.A.20(a)(1) and 66.A.20(a)(3)(ii) personnel, minor scheduled line maintenance means any minor scheduled inspection/check up to and including a weekly check specified in the aircraft maintenance programme. For aircraft maintenance programmes that do not specify a weekly check, the competent authority will determine the most significant check that is considered equivalent to a weekly check.

2. Typical tasks permitted after appropriate task training to be carried out by the 66.A.20(a)(1) and the 66.A.20(a)(3)(ii) personnel for the purpose of these personnel issuing an aircraft certificate of release to service as specified in 145.A.50 as part of minor scheduled line maintenance or simple defect rectification are contained in the following list:

(a) Replacement of wheel assemblies.

(b) Replacement of wheel brake units.

(c) Replacement of emergency equipment.

(d) Replacement of ovens, boilers and beverage makers.

(e) Replacement of internal and external lights, filaments and flash tubes.

(f) Replacement of windscreen wiper blades.

(g) Replacement of passenger and cabin crew seats, seat belts and harnesses.

(h) Closing of cowlings and refitment of quick access inspection panels.

(i) Replacement of toilet system components but excluding gate valves.

(j) Simple repairs and replacement of internal compartment doors and placards but excluding doors forming part of a pressure structure.

(k) Simple repairs and replacement of overhead storage compartment doors and cabin furnishing items.

(l) Replacement of static wicks.

(m) Replacement of aircraft main and APU aircraft batteries.

(n) Replacement of in-flight entertainment system components other than public address.

(o) Routine lubrication and replenishment of all system fluids and gases.

(p) The de-activation only of sub-systems and aircraft components as permitted by the operator’s minimum equipment list where such de-activation is agreed by the competent authority as a simple task.

(q) Inspection for and removal of de-icing/anti-icing fluid residues, including removal/closure of panels, cowls or covers or the use of special tools.

(r) Any other task agreed by the competent authority as a simple task for a particular aircraft type. This may include defect deferment when all the following conditions are met:

— There is no need for troubleshooting; and

— The task is in the MEL; and

— The maintenance action required by the MEL is agreed by the competent authority to be simple.

In the particular case of helicopters, and in addition to the items above, the following:

(s) removal and installation of Helicopter Emergency Medical Service (HEMS) simple internal medical equipment.

(t) removal and installation of external cargo provisions (i.e., external hook, mirrors) other than the hoist.

(u) removal and installation of quick release external cameras and search lights.

(v) removal and installation of emergency float bags, not including the bottles.

(w) removal and installation of external doors fitted with quick release attachments.

(x) removal and installation of snow pads/skid wear shoes/slump protection pads.

No task which requires troubleshooting should be part of the authorised maintenance actions. Release to service after rectification of deferred defects should be permitted as long as the task is listed above.

3. The requirement of having appropriate aircraft-rated certifying staff qualified as category B1, B2, B2L, B3, L, as appropriate, in the case of aircraft line maintenance does not imply that the organisation must have B1, B2, B2L, B3 and L personnel at every line station. The MOE should have a procedure on how to deal with defects requiring those categories of certifying staff.

4. The competent authority may accept that in the case of aircraft line maintenance an organisation has only B1, B2, B2L, B3 or L certifying staff, as appropriate, provided that the competent authority is satisfied that the scope of work, as defined in the MOE, does not need the availability of all those categories of certifying staff. Special attention should be taken to clearly limit the scope of scheduled and non-scheduled line maintenance (defect rectification) to only those tasks that can be certified by the available category of certifying staff.

145.A.30(h) Category C staff

Any organisation maintaining aircraft, except where stated otherwise in point (j), shall:

1. in the case of base maintenance of complex motor-powered aircraft, have appropriate aircraft-type-rated certifying staff, qualified as category C in accordance with Annex III (Part-66) and point 145.A.35. In addition, the organisation shall have sufficient aircraft-type-rated staff qualified as category B1 and B2, as appropriate, in accordance with Annex III (Part-66) and point 145.A.35 to support the category C certifying staff.

(i) Category B1 and B2 support staff shall ensure that all relevant tasks or inspections have been carried out to the required standard before the category C certifying staff issues the certificate of release to service.

(ii) The organisation shall maintain a register of any such category B1 and B2 support staff.

(iii) The category C certifying staff shall ensure that compliance with point (i) has been met and that all work required by the customer has been accomplished during the particular base maintenance check or work package, and shall also assess the impact of any work not carried out, with a view to either requiring its accomplishment or agreeing with the operator to defer such work to another specified check or time limit.

2. in the case of base maintenance of aircraft other than complex motor-powered aircraft, have one of the following:

(i) appropriate aircraft-rated certifying staff, qualified as category B1, B2, B2L, B3 and L, as appropriate, in accordance with Annex III (Part-66) and point 145.A.35;

(ii) appropriate aircraft-rated certifying staff, qualified in category C and assisted by support staff, as set out in point 145.A.35(a)(i).

AMC 145.A.30(h) Qualifications

In accordance with 145.A.30(h) and 145.A.35, the qualification requirements (basic licence, aircraft ratings, recent experience and continuation training) are identical for certifying staff and for support staff. The only difference is that support staff cannot hold certification privileges when performing this role since during base maintenance the release to service will be issued by category C certifying staff.

Nevertheless, the organisation may use as support staff (for base maintenance) persons who already hold certification privileges for line maintenance.

145.A.30(i) Component certifying staff

Component certifying staff shall be qualified in accordance with Article 5(6) and point 145.A.35.

Article5(6)

Until specific requirements for certifying staff for components are added to this Regulation, the requirements laid down in the national laws in force in the relevant Member State shall continue to apply, except for maintenance organisations located outside the Union where the requirements shall be approved by the Agency.

145.A.30(j) Special conditions

By derogation to points (g) and (h), in relation to the obligation to comply with Annex III (Part-66), the organisation may use certifying staff qualified in accordance with the following provisions:

1. For organisation facilities located outside the Community territory certifying staff may be qualified in accordance with the national aviation regulations of the State in which the organisation facility is registered subject to the conditions specified in Appendix IV to this Part.

2. For line maintenance carried out at a line station of an organisation which is located outside the Community territory, the certifying staff may be qualified in accordance with the national aviation regulations of the State in which the line station is based, subject to the conditions specified in Appendix IV to this Part.

3. For a repetitive pre-flight airworthiness directive which specifically states that the flight crew may carry out such airworthiness directive, the organisation may issue a limited certification authorisation to the aircraft commander and/or the flight engineer on the basis of the flight crew licence held. However, the organisation shall ensure that sufficient practical training has been carried out to ensure that such aircraft commander or flight engineer can accomplish the airworthiness directive to the required standard.

4. In the case of aircraft operating away from a supported location the organisation may issue a limited certification authorisation to the commander and/or the flight engineer on the basis of the flight crew licence held subject to being satisfied that sufficient practical training has been carried out to ensure that the commander or flight engineer can accomplish the specified task to the required standard. The provisions of this point shall be detailed in an exposition procedure.

AMC 145.A.30(j)(4) Limited certification authorization

1. For the issue of a limited certification authorisation:

(a) the commander should hold either an air transport pilots license (ATPL), or a commercial pilots license (CPL).

(b) The flight engineer should hold either an ATPL, CPL or a national flight engineer licence acceptable to the competent authority on the aircraft type.

2. In addition the limited certification authorisation is subject to the maintenance organisation exposition containing procedures to address the personnel requirements of 145.A.30(e) and associated AMC and guidance material. The procedures should be accepted by the competent authority and should include as a minimum:

(a) Completion of adequate maintenance airworthiness regulation training.

(b) Completion of adequate task training for the specific task on the aircraft. The task training should be of sufficient duration to ensure that the individual has a thorough understanding of the task to be completed and will involve training in the use of associated maintenance data.

(c) Completion of the procedural training as specified in Part-145.

2.(i) Typical tasks that may be certified and/or carried out by the commander holding an ATPL or CPL are minor maintenance or simple checks included in the following list:

(a) Replacement of internal lights, filaments and flash tubes.

(b) Closing of cowlings and refitment of quick access inspection panels.

(c) Role changes e.g. stretcher fit, dual controls, FLIR, doors, photographic equipment etc.

(d) Inspection for and removal of de-icing/anti-icing fluid residues, including removal/closure of panels, cowls or covers that are easily accessible but not requiring the use of special tools.

(e) Any check/replacement involving simple techniques consistent with this AMC and as agreed by the competent authority.

2.(ii) Holders of flight engineer licence acceptable to the competent authority on the aircraft type, may only exercise this limited certification authorisation privilege when performing the duties of a flight engineer.

In addition to paragraph 2(i)(a) to (e) other typical minor maintenance or simple defect rectification tasks that may be carried out are included in the following list:

(a) Replacement of wheel assemblies.

(b) Replacement of simple emergency equipment that is easily accessible.

(c) Replacement of ovens, boilers and beverage makers.

(d) Replacement of external lights.

(e) Replacement of passenger and cabin crew seats, seat belts and harnesses.

(f) Simple replacement of overhead storage compartment doors and cabin furnishing items.

(g) Replacement of static wicks.

(h) Replacement of aircraft main and APU aircraft batteries.

(i) Replacement of in-flight entertainment system components other than public address.

(j) The de-activation only of sub-systems and aircraft components as permitted by the operator’s minimum equipment list where such de-activation is agreed by the competent authority as a simple task.

(k) Re-setting of tripped circuit breakers under the guidance of maintenance control.

(l) Any other task agreed by the competent authority as a simple task for a particular aircraft type.

3. The authorisation should have a finite life of twelve months subject to satisfactory re-current training on the applicable aircraft type.

GM 145.A.30(j)(4) Flight engineer

For the holder of a flight engineer licence acceptable to the competent authority appendix 1 to JAR FCL 4.160 Technical Training Course (TTC) details the following subjects:

Familiarisation with basic maintenance procedures, to give additional technical background knowledge, especially with respect to the implication of systems malfunctions, and to train the applicant in maintenance related to the Minimum equipment list (MEL).

The theoretical knowledge instruction consists of 100 hours and includes the following elements:

1. Airframe and systems

2. Electrics

3. Powerplant and emergency equipment

4. Flight instruments and automatic flight control systems

Practical skills training provided by an organisation approved under Part-145 is given which includes 35 hours practical experience in the following subjects:

— Fuselage and flight controls,

— Engines,

— Instruments,

— Landing gear and brakes,

— Cabin/cockpit/emergency equipment,

— De-icing/anti-icing related maintenance activities;

— Ground handling and servicing,

— Certificate of completion.

Following successful completion of the technical training, the training organisation carrying out the theoretical knowledge instruction and/or the practical skill training should provide the applicant with a certificate of satisfactory completion of the course, or part thereof.

5. In the following unforeseen cases, where an aircraft is grounded at a location other than the main base where no appropriate certifying staff are available, the organisation contracted to provide maintenance support may issue a one-off certification authorisation:

AMC 145.A.30(j)(5) One-off authorisation

1. For the purposes of this sub-paragraph ‘unforeseen’ means that the aircraft grounding could not reasonably have been predicted by the operator because the defect was unexpected due to being part of a hitherto reliable system.

2. A one-off authorisation should only be considered for issue by the quality department of the contracted organisation after it has made a reasoned judgement that such a requirement is appropriate under the circumstances and at the same time maintaining the required airworthiness standards. The organisation’s quality department will need to assess each situation individually prior to the issuance of a one-off authorisation.

3. A one-off authorisation should not be issued where the level of certification required could exceed the knowledge and experience level of the person it is issued to. In all cases, due consideration should be given to the complexity of the work involved and the availability of required tooling and/or test equipment needed to complete the work.

(i) to one of its employees holding equivalent type authorisations on aircraft of similar technology, construction and systems; or

AMC 145.A.30(j)(5)(i) Procedures

In those situations where the requirement for a one-off authorisation to issue a CRS for a task on an aircraft type for which certifying staff does not hold a type-rated authorisation has been identified, the following procedure is recommended:

1. Flight crew should communicate full details of the defect to the operator’s supporting maintenance organisation. If necessary, the supporting maintenance organisation will then request the use of a one-off authorisation from the quality department.

2. When issuing a one-off authorisation, the quality department of the organisation should verify that:

(a) Full technical details relating to the work required to be carried out have been established and passed on to the certifying staff.

(b) The organisation has an approved procedure in place for coordinating and controlling the total maintenance activity undertaken at the location under the authority of the one-off authorisation.

(c) The person to whom a one-off authorisation is issued has been provided with all the necessary information and guidance relating to maintenance data and any special technical instructions associated with the specific task undertaken. A detailed step by step worksheet has been defined by the organisation, communicated to the one-off authorisation holder.

(d) The person holds authorisations of equivalent level and scope on other aircraft type of similar technology, construction and systems.

3. The one-off authorisation holder should sign off the detailed step by step worksheet when completing the work steps. The completed tasks should be verified by visual examination and/or normal system operation upon return to an appropriately approved Part-145 maintenance facility.

(ii) to any person with not less than five years maintenance experience and holding a valid ICAO aircraft maintenance licence rated for the aircraft type requiring certification provided there is no organisation appropriately approved under this Part at that location and the contracted organisation obtains and holds on file evidence of the experience and the licence of that person.

AMC 145.A.30(j)(5)(ii) Qualifications

This paragraph addresses staff not employed by the maintenance organisation who meet the requirements of 145.A.30(j)(5). In addition to the items listed in AMC 145.A.30(j)(5)(i), paragraph 1, 2(a), (b) and (c) and 3 the quality department of the organisation may issue such one-off authorisation providing full qualification details relating to the proposed certifying personnel are verified by the quality department and made available at the location.

All such cases as specified in this point must be reported to the competent authority within seven days after issuing such certification authorisation. The organisation issuing the one-off authorisation shall ensure that any such maintenance that could affect flight safety is re-checked by an appropriately approved organisation.

145.A.30(k) Airworthiness review staff

If the organisation performs airworthiness reviews and issues the corresponding airworthiness review certificate in accordance with point ML.A.903 of Annex Vb (Part-ML), it shall have airworthiness review staff qualified and authorised and meeting all of the following requirements:

1. shall hold a certifying staff authorisation for the corresponding aircraft;

2. shall have at least three years of experience as certifying staff;

3. shall be independent from the continuing airworthiness management process of the aircraft being reviewed or shall have overall authority on the continuing airworthiness management process of the complete aircraft being reviewed;

4. shall have acquired knowledge of Subpart C of this Annex (Part-M) or Subpart C of Annex Vb (Part-ML);

5. shall have acquired proven knowledge of the procedures of the maintenance organisation relevant to the airworthiness review and issue of the airworthiness review certificate;

6. shall have been formally accepted by the competent authority after having performed an airworthiness review under the supervision of the competent authority or under the supervision of the organisation’s airworthiness review staff in accordance with a procedure approved by the competent authority;

7. shall have performed at least one airworthiness review in the last twelve-month period.